The Ultimate Guide to Paper Cup Machines: Efficiency, Types, and Benefits

The Ultimate Guide to Paper Cup Machines: Efficiency, Types, and Benefits

In today’s fast-paced world, single-use packaging solutions are in high demand, and paper cups remain a popular choice for beverages. Central to their production is the Paper Cup Machine, a vital piece of equipment for businesses in the food and beverage industry. This guide explores everything you need to know about these machines, from their efficiency and various types to the benefits they offer.

How Paper Cup Making Machines Work

Paper cup machines automate the process of transforming paper rolls into finished cups. The process typically involves unwinding the paper, printing designs if needed, coating for waterproofing, forming the cup shape, sealing the side seam, and attaching the bottom. Advanced models integrate multiple stages, ensuring high-speed production with minimal manual intervention.

Key Types of Paper Cup Forming Equipment

There are several types of paper cup machines tailored to different production needs:

• Automatic Paper Cup Machines: Fully automated systems that handle the entire process from paper feeding to cup output, ideal for large-scale production.

• Semi-Automatic Paper Cup Machines: Require some manual operation, suitable for small to medium businesses with moderate output requirements.

• Single-Side and Double-Side PE Coating Machines: These apply a polyethylene layer to make cups leak-proof and suitable for both hot and cold drinks.

Benefits of Investing in a Paper Cup Production Line

Using a dedicated paper cup machine offers numerous advantages:

• High Efficiency and Speed: Modern machines can produce thousands of cups per hour, reducing labor costs and increasing output.

• Cost-Effectiveness: Bulk production lowers per-unit costs, improving profit margins.

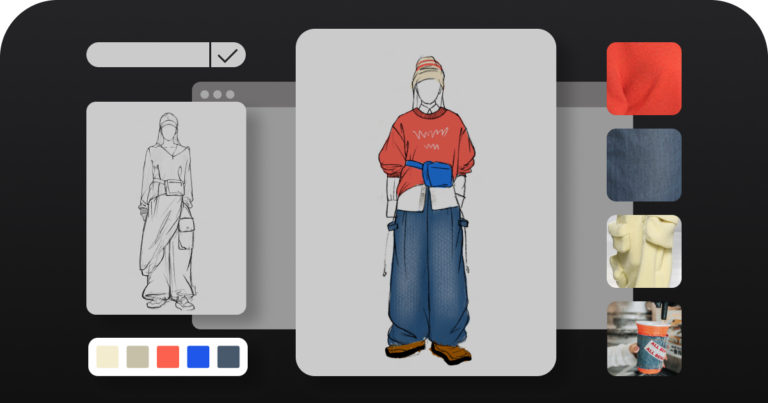

• Customization and Versatility: Machines can be adjusted for different sizes, shapes, and designs, allowing brands to create unique products.

• Eco-Friendly Options: Many machines support biodegradable materials, aligning with sustainable packaging trends.

Common Questions About Paper Cup Manufacturing

What is the production capacity of a standard paper cup machine?

Capacity varies by model, but automatic machines can produce 40–100 cups per minute, depending on cup size and complexity.

Are paper cup machines easy to maintain?

Yes, with regular cleaning and part inspections, these machines are designed for durability and easy upkeep.

Can I produce both hot and cold drink cups with one machine?

Absolutely! Many machines are versatile and can manufacture cups for various temperatures by adjusting materials and coatings.

Maximize Your Packaging Efficiency Today

Ready to boost your production capabilities? Investing in a reliable paper cup machine streamlines your operations, reduces costs, and supports brand growth. Explore our range of high-performance machines and find the perfect solution for your business needs.

Contact us now to request a quote or schedule a demo!